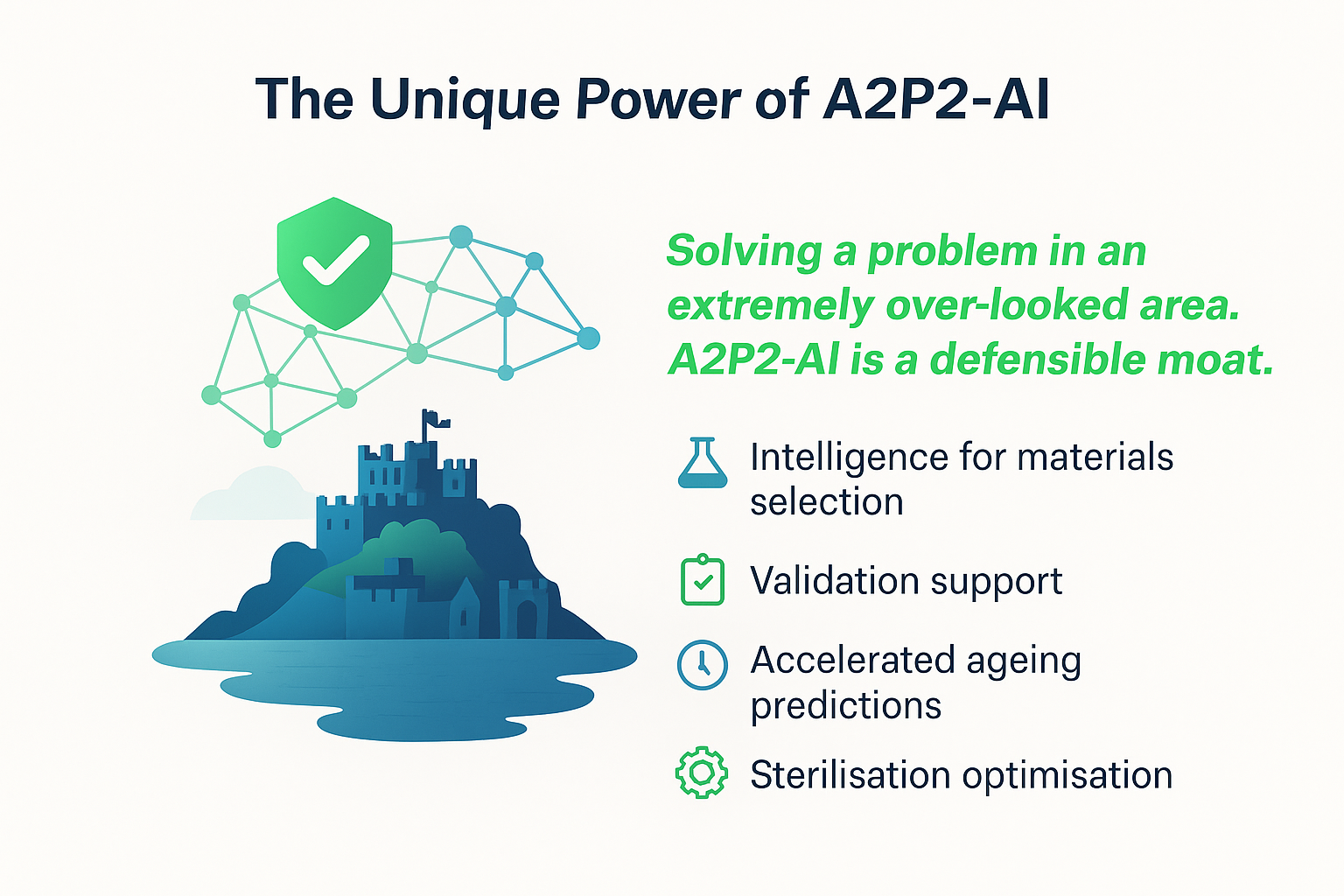

GULSINE: Revolutionising Product Stability and Accelerating Market Readiness with A2P2 Software

GULSINE proudly presents A2P2, an innovative platform engineered to address complex stability challenges and streamline product introduction. Leveraging state-of-the-art mathematical models, A2P2 accurately predicts the shelf-life of critical products, empowering businesses to build resilient supply chains, accelerate time-to-market, and enhance sustainability—all while reducing costs and resource consumption.

Key Benefits of A2P2:

Accelerated Product Release: Confidently bring products to market faster by eliminating the need for lengthy, energy-intensive stability tests.

Resilient Supply Chains: Ensure product durability and reliability, even under varying environmental conditions, to minimize disruptions and maximize efficiency.

Resource Optimization: Save time, energy, and materials by replacing traditional testing methods with precise, data-driven predictions.

Sustainability Advancements: Reduce carbon emissions and environmental impact associated with conventional stability testing processes.

Versatile Applications

A2P2 is applicable to any product containing plastic components or packaging, as well as assemblies incorporating metals, ceramics, or adhesives. Recent projects include:

Pacemakers: Ensuring the longevity and reliability of life-saving medical devices.

Biopharmaceutical Bags and Bioreactors: Validating the shelf-life of critical healthcare products.

Single-Use Consumables: Optimizing the performance and durability of disposable medical and industrial components.

How A2P2 Works

A2P2 leverages advanced mathematical models and a comprehensive library of ageing data to predict the long-term behavior of polymers and products. Whether it’s medical devices, pharmaceuticals, packaging, or consumer goods, A2P2 provides:

Guided Experimental Design: Optimize data collection for complex samples.

Scenario Modeling: Simulate real-world conditions to predict shelf-life.

Part Diagnostics: Identify material weaknesses and manufacturing issues.

Sustainability Solutions: Evaluate biopolymers and eco-friendly alternatives.

Proven Results

266 Days Saved: Accelerated ageing studies for a bioreactor reduced testing time from 337 days to just 71 days, enabling faster FDA approval.

£40M Saved: Extended the shelf-life of a critical epoxy-based glue, preventing costly waste.

Extended Shelf-Life: Enabled medical devices and pharmaceuticals to reach markets with longer, validated lifespans.

Join the Innovation Movement

A2P2 is not just a tool—it’s a paradigm shift in product development. By replacing outdated, energy-intensive testing methods, A2P2 empowers businesses to:

Challenge the Status Quo: Drive regulations, don’t let them drive you.

Understand Your Products Better: Gain unparalleled insights into material behavior and performance.

Lead in Sustainability: Reduce waste, extend product lifespans, and support a greener future.

Experience A2P2 Today

Discover how A2P2 can transform your product development process. Contact us for a free demonstration and see how you can save time, reduce costs, and accelerate innovation.

Connect with Dr. Nazli on LinkedIn: LinkedIn Profile

A2P2: Redefining Shelf-Life Prediction for a Faster, Smarter, and Sustainable Future.

A2P2 Interface

🚨 New Product Announcement 🚨

🎉 Introducing A2P2 GPT

The World’s First AI Assistant for Polymer Ageing & Modelling

Used for designing innovative accelerated aging studies

Predictive aging modelling

Now available by monthly or yearly subscription.

🧠 A2P2 GPT – Your Expert in Polymer Ageing & Lifetime Prediction

Built by Gulsine Ltd. | Powered by OpenAI | Guided by Dr. Ozdemir

🚀 Accelerate Your Product’s Journey to Market — With Confidence

A2P2 GPT is your always-on digital assistant for polymer ageing, shelf-life prediction, and accelerated aging study design.

Trained on decades of proprietary research, peer-reviewed science, and the innovative A2P2 methodology, this AI delivers fast, accurate insights for biotech, medical devices, biopharma, and any material-focused industry.

🔬 Accelerated Ageing Study Design

Organise ageing studies tailored to your product’s material, regulatory target, and end-use.

Get actionable creative test plans — instantly.

📋 Regulatory Support

Collect your own raw data with the guidance of A2P2 GPT for ISO, FDA, EMA or ICH submissions.

Get guidance for physical, chemical, and hydrolysis-driven degradation.

🔁 Live Intelligence, Updated Daily

A2P2 GPT evolves every day with the latest ageing data and materials science research — it's not just a database, it's a live assistant.

⚙️ Who Is A2P2 GPT For?

Biotech & Medtech developers with shelf-life validation needs

Pharma packaging teams working with complex multi-layer materials

Materials engineers & consultants modeling real-world polymer behavior

Sustainability leads validating biodegradable or recycled materials

Academic & industry researchers building new accelerated ageing models

— Helps the user along every stage of product development from concept to market

A2P2 solves complex stability challenges to reduce time, waste and energy and save resources for organisations.

A2P2 helps products last longer and promotes re-use, creating a circular economy.

We help release innovative healthcare solutions to market faster, aiding in the fight against diseases. Our technology speeds up product release and makes product validation and certification easier and more reliable by eliminating the need of years of carbon-intensive accelerated ageing tests.

We extend the shelf-life of products and create resilient supply chains, eliminating the issue of cancelled orders.

Gulsine’s method is validated with regulatory approvals.

How many devices get thrown away thinking they are

past their useful life ?

A2P2 helps plastics manufacturers understand their products better.

“Traditional stability testing account for up to 10% of the carbon emissions involved in product lifecycle.”

MOTIVATION

In industry, many products compose of a combination of materials including plastics. As plastics age, their properties change with time. Device manufacturers need to understand and appreciate plastics ageing to define devices' lifespan. In this regard, polymers ageing knowledge is very valuable. Determining a product's shelf life can be one of the most challenging aspects of product development. It is also one of the most overlooked.

To develop a reliable shelf life claim, product manufacturers must simulate the full life cycle of a device as close as possible to reality by using accelerated ageing measures. Owing to these variables, the process for establishing the device shelf life is sophisticated and involves rigorous testing.

While designing stability tests, most manufacturers overlook the fact that multiple ageing mechanisms take place concurrently and estimate shelf life for devices relying on oxidative ageing only. Shelf life claims that rely solely on oxidative ageing are extraordinarily conservative and have a big potential for extension by taking into consideration the faster ageing mechanisms.

Let’s work together

Interested in working together? Fill out some info and we will be in touch shortly! We can't wait to hear from you!